AquaBright Pool Finish

aquaBRIGHT is a long lasting stain and crack resistant thermo-polymer finish that comes with an industry leading 10 year pro rata warranty. aquaBRIGHT is a pool finish suitable for fibreglass and concrete pool renovations, new builds, pool resurfacing, and is designed to simplify pool maintenance.

There is a wide range of attractive colours to choose from that won’t fade over time, while the surface of the finish is engineered to be a soft feeling material. aquaBRIGHT has been used for both residential and commercial pool/water park resurfacing projects around the world since 2008.

In the late 1980s United States Government regulations banned crucial ingredients to the widely used silky brilliant white rubber-based paint pool finish, known for its durability against stains and imperfections. Paint finishes developed after this were no longer free from imperfections, and commonly used plaster finishes have their own drawbacks.

aquaBRIGHT eliminates the shortcomings of traditional pool finishes such as paint and plaster. Paint finishes are prone to cracking, blistering, peeling and fading, while plaster has long and complicated start-up processes (hot-start), plus staining, shrinking and cracking problems. aquaBRIGHT is a scientifically developed thermo-polymer finish designed to eliminate these issues and simplify pool maintenance.

Colour Uniformity

Colour pigments are encapsulated in the aquaBRIGHT polymer resin during the manufacturing process and cannot react with pool water chemistry. As a result aquaBRIGHT has a more uniform colour across the entire swimming pool and will not “mottle” or fade over time.

Why Pay for Trucked Water?

If left alone, most curing masonry finishes will dry out and crack if water is not immediately placed in the pool. Because of this, it is a common practice to truck in water to protect the new finish. Once installed, the aquaBRIGHT finish is cured. You can fill that day, the next day or the following week; thus eliminating the need to pay for water.

What’s a Hot Start?

Coloured masonry finishes typically require a two week start up process called a “low alkalinity burn” or a “hot start,” which involves pouring muriatic acid into your pool to burn the leaching calcium off the curing masonry finish. A new aquaBRIGHT finish can be filled immediately, just “balance and swim.”

Pre-mix To Protect

Usually chemicals need to be pre-mixed with water before being added to protect the finish of the pool to prevent problems like bleaching and etching. As aquaBRIGHT is chemical resistant and unlike masonry finishes, aquaBRIGHT can be acid washed with very little impact to the surface or colour.

Chemical Resistant, PH Neutral

Unlike plaster or masonry surfaces, aquaBRIGHT is inert and does not react with water chemistry. Since there is no reaction between the water and cementitious surfaces the pH is much easier to balance and keep stable, which means a pool coated with the smooth, non-porous and pH neutral aquaBRIGHT finish will use less chemicals. aquaBRIGHT is approved for installation in swimming pools and spas heated up to 40C, and is resistant to blistering, chalking, peeling, cracking and other signs of deterioration and use.

Eco-Friendly

aquaBRIGHT is an eco-friendly product that requires less energy resources to manufacture and transport than other pool finishes, and has zero end-of-job waste to be disposed in landfills. Fewer chemicals are required over the life of the pool meaning reduced chemical exposure in the backyard. aquaBRIGHT pool finishes will outlast traditional finishes and therefore reduce/eliminate the energy expenditure and waste of refurbishments over the life of the pool.

AquaBright Colour Chart ( Please click on the tile to see more )

*Colours shown on this website may vary from the actual colours applied to your pool

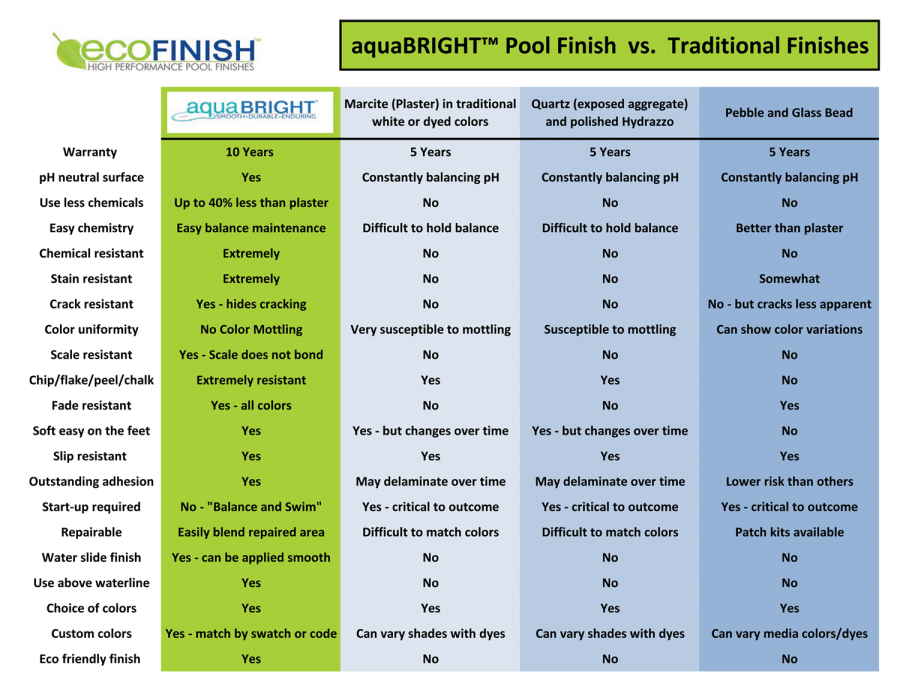

AquaBright vs Traditional Finishes Talking Points

Check Out Our Video

-

AquaBright vs Traditional Finishes Talking Points

Please download our aquaBRIGHT vs Traditional Pool Finishes talking point, it includes warranty and valuable product information.

Technical Data Sheet

Performance Copolymer Coating

AquaBright™ is a copolymer of ethylene and methacrylic acid, made with nominally 10 wt% methacrylic acid. It is inherently flexible without the need for plasticizers. The resin is pigmented and UV-stabilized for exterior applications.

Aqua Bright™ is a revolutionary pool finish that virtually eliminates all of traditional plaster and paint coating shortcomings. It is resistant to chipping, peeling and scratching. It cures in seconds and is extremely durable. Aqua Bright is very eco-friendly because it greatly reduces the use of chemicals to balance pH. Also, the amount of fossil fuels needed to mine, transport and apply plaster are no longer used. So, whether you are renovating or building a new swimming pool, AquaBright is the wave of the future when seeking a plaster or paint alternative.